Application

CE marked online particle counter adopts the counting principle of photoresist (shading) method specified by the International Hydraulic Standards Committee, which is specially used for on-site online measurement and detection device of oil contamination level. It has the advantages of small size, light weight, fast detection speed, high precision and good repeatability, and can work under high temperature and high pressure and other harsh conditions. Suitable for engine oil, gear oil, transformer oil (ie insulating oil), hydraulic oil, lubricating oil, synthetic oil, water-based (water-based hydraulic oil, water glycol, etc.), alcohols, ketones, etc. Solvent, can be widely used in aerospace, petrochemical, transportation ports, iron and steel metallurgy, automobile manufacturing and other fields.

Feature

1. Using the principle of photoresist (shading) method, using high-precision laser sensor, small size, high precision and stable performance

2.Suitable for on-site online detection, which can monitor the particle pollution in the oil system in real time

3.Built-in data analysis system, which can display the real data of particle size of each channel and automatically determine the sample grade

4.Standard model can withstand pressure up to 100kg directly, optional pressure reducing valve is used for high pressure measurement of 400kg

5.With volume flushing and long flushing modes, it is convenient for users to use and maintain the equipment

6.Built-in ISO4406, NAS1638, SAE4059, GJB420A, GJB420B, ГOCT17216, GB/T14039 and other particle pollution level standards, one test can give all built-in standard results

7.Built-in calibration function, can be calibrated according to GB/T21540, ISO4402, ISO11171, GB/T18854 and other standards

8. All standard and arbitrary alarm levels can be set independently to realize pollution or cleanliness detection

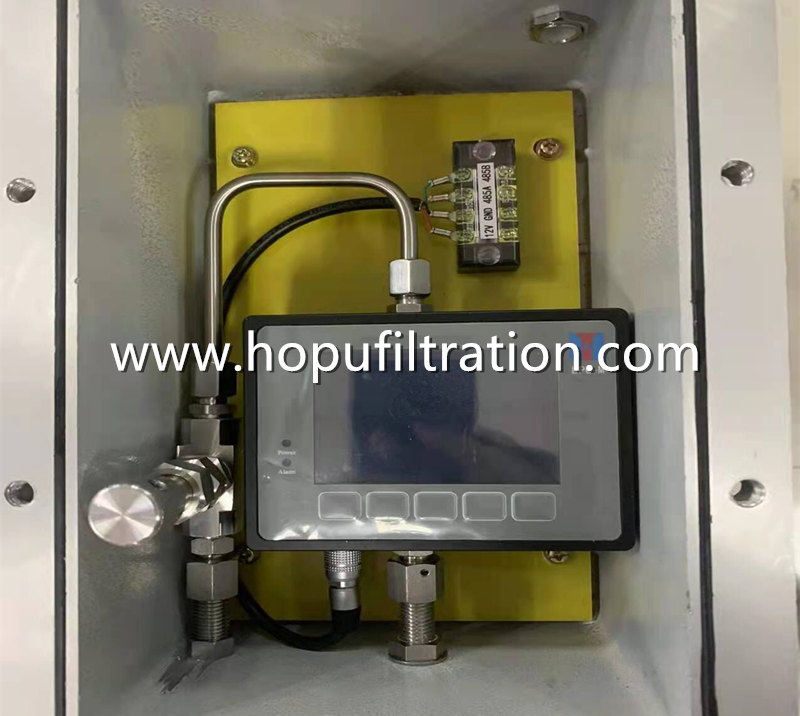

9. RS232 or RS485 interface, support standard modbus protocol, can connect to computer, host computer, printer, PLC system or other equipment for data monitoring and processing

10. Large storage, you can choose to store in the instrument internal or external USB storage device

11. Sturdy exterior structure, suitable for complex working environment

The position of the double oil outlet can be selected up and down, which is easy to install

12. Can test continuously or set test time interval arbitrarily

13.The instrument interface can freely control the switch of the remote printer

14.Chinese and English dual system, customers can switch freely, suitable for export

15.Touch screen operation or membrane keys, customers can switch freely

16.Optional 4G module, support remote data monitoring, historical data, curve query on mobile phone or computer (optional)

17. Optional built-in moisture and temperature sensor module, which can output four parameter information at the same time (optional)

Technical data

1.Light source: semiconductor laser

2.Flow rate range: 10-500mL/min

3.Test sample viscosity: ≤350cSt

4.On-line detection pressure: 0.1-10Mpa (the maximum pressure of the optional decompression device can reach 40Mpa)

5.Particle size range: 1-600μm

6.Interface: USB interface, RS232 interface, RS485 interface

7.Data storage: Provide 1000 groups of data storage space and support USB storage

8.Sensitivity: 1μm or 4μm (c)

9. Overlap error limit: 40,000 grains/ml

10.Counting volume: 1-999ml

11.Counting accuracy: ±0.5 pollution degree levels

12. Protection class: IP56

13.Temperature acquisition T (optional): 1. Acquisition range: 1-100 degrees Celsius; 2. Measurement accuracy: 1 degree Celsius;

14.Water activity collection aw (optional): 1. Collection range: 1-100%RH; 2. Measurement accuracy: 1%RH;

15.Absolute water content AH (optional): 1. Collection range: 1-300ppm; 2. Measurement accuracy: 1ppm;

16.Test interval: 1 second - 24 hours

17.Test sample temperature: 0-80℃

18.Working temperature: -20-60℃

19.Storage temperature: -30-100℃

20.Power supply: AC 220V±10%, 50/60Hz or DC12-40V

21.Weight: 1.1kg

Volume: 115×85×60mm