Compact Transformer Oil Filtering And Degassing Machine Portable Insulation Oil Filtration Machine

HOPU Oil Filtering Machine Overview

ZY series single-stage vacuum transformer oil purifier is mainly used in electric power project, petroleum, chemical, mining,metallurgy, manufacturing and other industries to purify various types of unqualified insulating oil, such as No. 10, No. 25 No.45 transformer oil, mutual inductor oil, cable oil, switch oil, etc.

This insulation Oil Purifier is designed verticle vacuum chamber, which is bigger degassing cappacity, adopts Duplex-Stereo film evaporation technology, which can quickly and effectively remove water, gas and

impurities from oil under vacuum negative pressure, restore and improve the dielectric performance of the insulating oil, and effectively guarantee Power equipment operates safely. This machine can also be used for different purposes such as vacuum drying,vacuum oiling, and hot oil circulation.

FEATURES

◆ Strong ability to remove impurities: ultra-large area cylindrical precision filter element, with high filtration accuracy, easy

installation and replacement.

◆ High-efficiency vacuum dehydration and degassing: Duplex-Stereo film evaporation technology.

◆Excellent heating system: carbon fiber electric heater with long service life.

◆ Automatic control to realize unattended, safe and stable working.

◆ Safety interlock protection: oil pump, vacuum pump, heater interlock protection.

◆ Low noise, easy operation,long maintenance interval, low energy consumption, low operating cost.

◆ It can be used together with the insulation oil

regeneration device, which has the effect of decoloring, deacidification, deoxidation and removing free carbon and other harmful

substances from the oil.

Single Stage Vacuum Transformer Oil Degassing and Filtration Machine Technical Specs (for reference only)

| Parameters | Unit | ZY/ZYA-10 | ZY/ZYA-20 | ZY/ZYA-30 | ZY/ZYA-50 | ZY/ZYA-100 | ZY/ZYA-150 | ZY/ZYA-200 | ZY/ZYA-300 |

| Flow rate | LPH | 600 | 1200 | 1800 | 3000 | 6000 | 9000 | 12000 | 18000 |

| Working vacuum | MPa | -0.06~-0.095 |

| Working pressure | MPa | ≤0.4 | ≤0.4 | ≤0.4 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

Working without trouble | H | ≤0.5 |

| Continuous working | H | ≥150 |

| Tempreature range | ℃ | 20~80 |

| Power supply |

| 380V, 3 phase, 50 Hz (or as per your requirements) |

| Working noise | dB(A) | ≤85 |

| Heating power | KW | 12 | 13 | 15 | 30 | 48 | 60 | 72 | 90 |

| Total power | KW | 13.5 | 14.5 | 16.5 | 33.5 | 53 | 65 | 76 | 98 |

| Inlet/Outlet caliber | mm | ф25 | ф25 | ф25 | ф32 | ф42 | ф50 | ф65 | ф65 |

| Weight | Kg | 230 | 250 | 280 | 300 | 550 | 700 | 950 | 1200 |

| Size | nm | 1050x750x1300 | 1100x850x1400 | 1150x900x1450 | 1200x950x1500 | 1600x1000x1800 | 1650x1100x1850 | 1800x1200x1900 | 1900x1200x2000 |

| After Filtration | Moisture(Water Content)≤5PPM |

| Gas Content ≤0.1% (Vol) |

Impurities Degree (Filtration precision) ≤ 5 micron |

| Breakdown Voltage (Dielectric) ≥65 ~ 70 KV |

Cleanliness ≤ NAS 1638 Grade 6

|

Advantage

It is a high-efficiency and economic type, with Duplex-Stereo film evaporation technology, and its efficiency is 3-5 times higher than that of the traditional flash vacuum oil purifier. It adopts interlocking protection device, full-automatic liquid level control system, and pressure protection system to realize unattended operation. The operation is simple, safe and reliable. The machine is compact, light and flexible, and easy to move

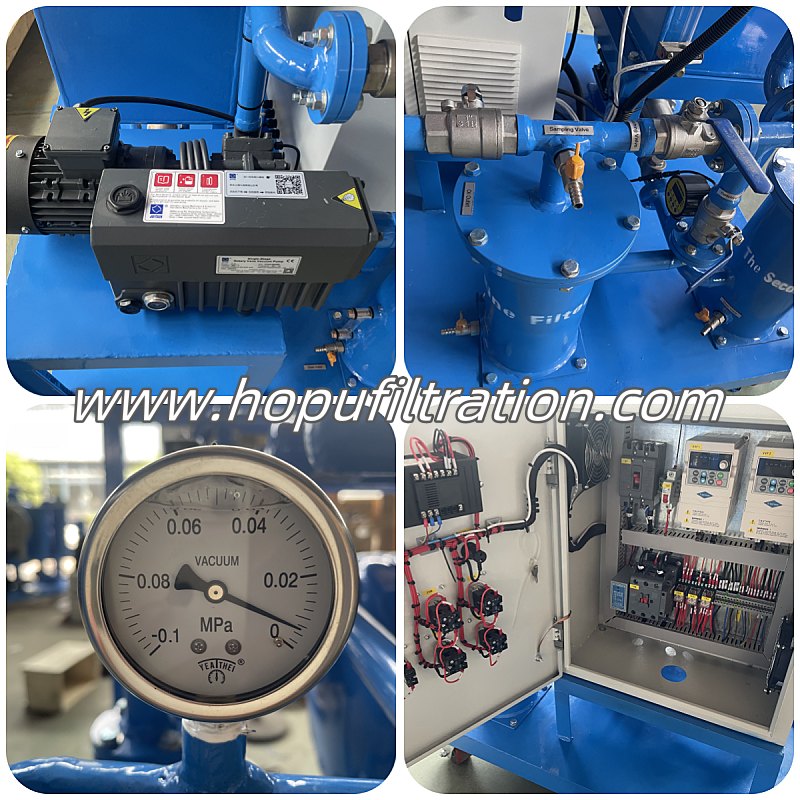

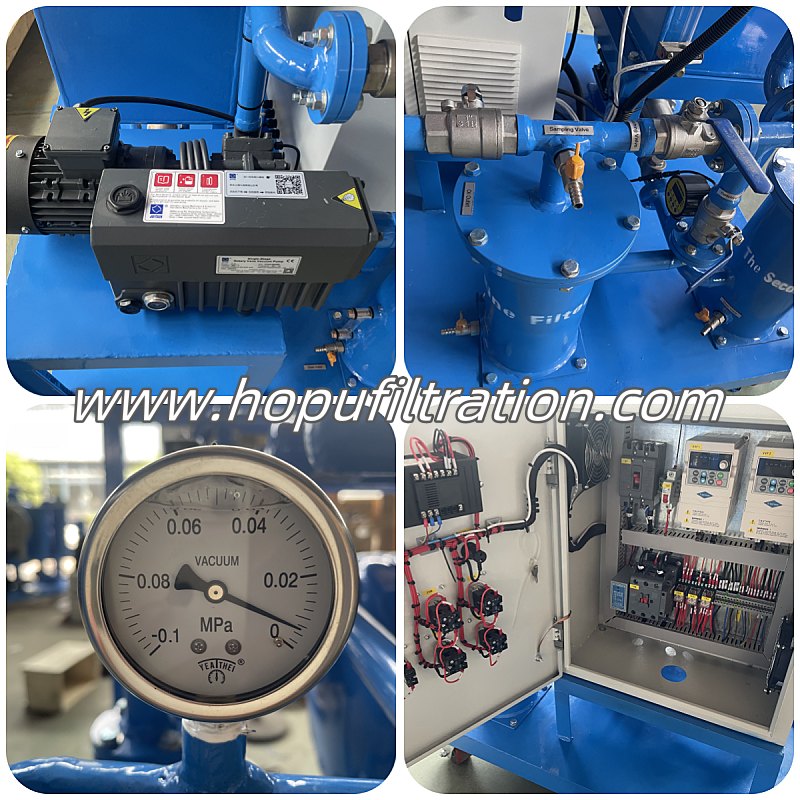

Vacuum System

It is composed of vacuum tank, vacuum pump, condensing tank, liquid accumulation tank, and air supplement system. The optimized structure design greatly increases the surface area of the oil in the vacuum system and maximizes the stroke of the oil in the vacuum system. Make the water and gas in the oil overflow sufficiently. This machine adopts an advanced anti-foaming system, so that the oil filter will never show the oil injection phenomenon that is common in similar products.

Filtration system

Three-stage filtration is adopted, and the coarse filter at the suction port protects the oil pump and prolongs the service life of the main filter. A two-stage fine filter is installed behind the pump to make the oil quickly reach a high degree of cleanliness. The filter material adopts special gradual aperture glass fiber material, which can filter particles of different sizes in layers, which greatly improves the service life of the filter element. With a complete filter element structure, it can effectively reduce the surface flow rate of the filter material and obtain stable filtration precision.

Heating system

It adopts step-by-step heating, the surface heat load is less than 1.0W/cm2, and the oil will not deteriorate due to overheating. The oil temperature can be arbitrarily adjusted from 0 to 100° C, automatically controlled, and equipped with a protection device. When the oil intake is too small, it will automatically stop working to avoid damage to the heater caused by dry burning.

Automatic control system

This machine adopts a series of automatic control instruments such as frequency converter, liquid transmitter, liquid level transmitter, temperature sensor, vacuum sensor, etc., to collect various information of equipment operation, and hand it to the central processor to process and automatically control the operation of the entire equipment and monitor the operating status of the equipment This machine is equipped with various protection devices (overload protection, edge voltage protection, phase sequence protection, abnormal operation shutdown protection) to ensure the safe operation of the equipment.