New Design Single Stage Vacuum Transformer Oil Purifier Application

It can satisfy the installation or maintenance field of transformer for pumping air into vacuum state, and at the same time complete the transformer oil degassing, dehydration processing, shorten the oil processing period.

This newly designed Vacuum Transformer Oil Purification System combines oil precision filtering, high efficiency of dewatering, degassing, vacuum stereo evaporation technology and automation control technology at an organic whole, the operation is simple, safe and reliable.

It can also be used to fill and transfer the insulating oil into the transformers, as well as storage tank to tank, tank to transformer.

After completion of dehydration, degassing and fine filtration process, the dissolved water, liquid water, trace water, dissolved gases, particles and tiny impurities can be removed completely to upgrade the properties of transformer insulating oil.

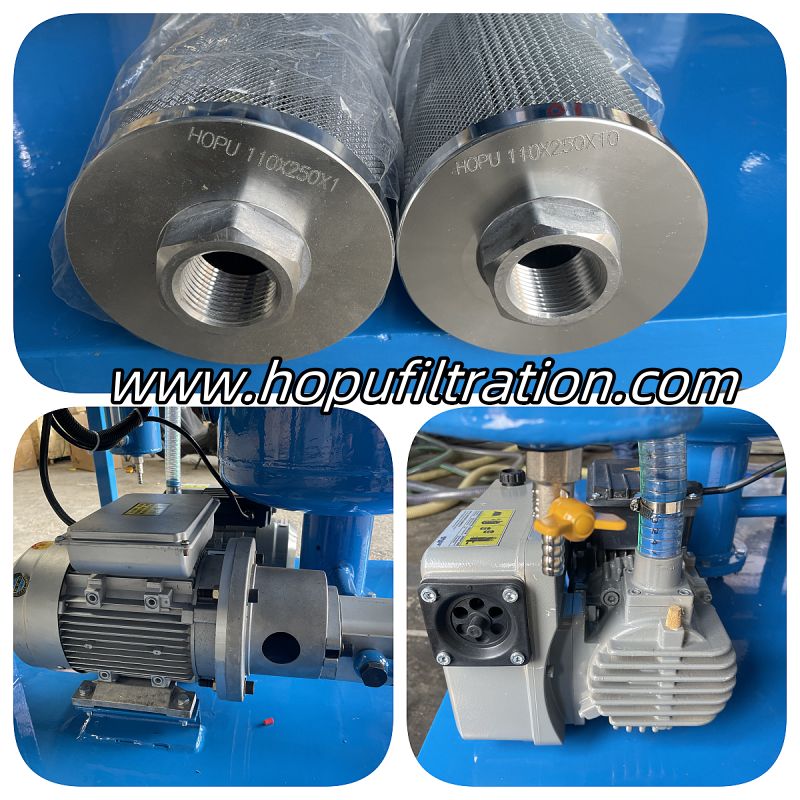

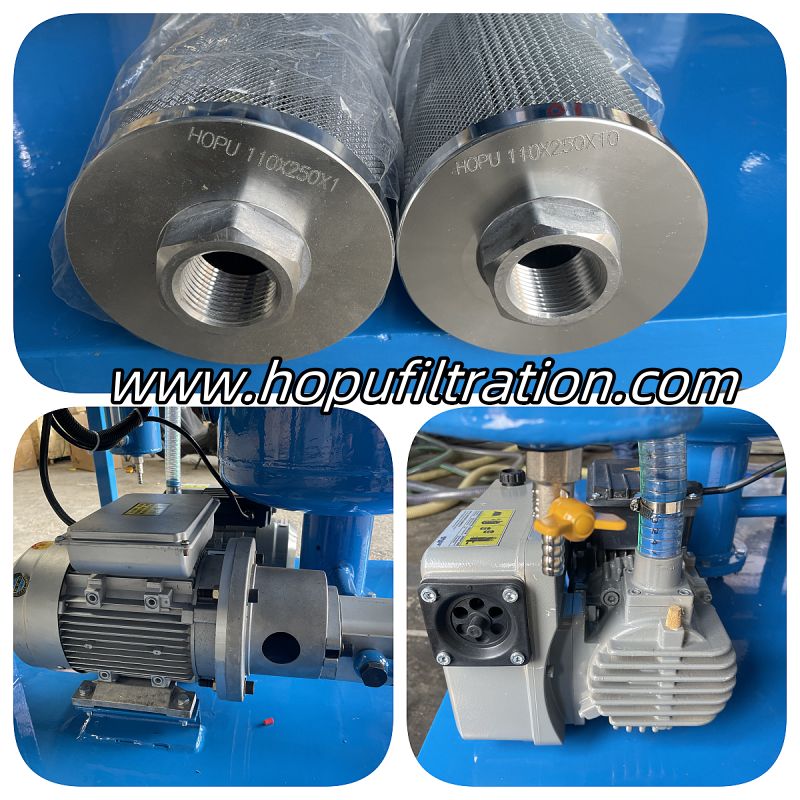

HOPU ZY Series Vacuum Transformer Oil Purification System Features

1.High filtration precision holds much of sludge, remove the fine particulates out from the oil.

2.Unique degassing, dehydrated material, its evaporation area one hundred times larger than conventional materials.

3.The Transformer Oil Purification System has the characteristics of small dimension and high efficiency, convenient movement, particularly suitable for live working in site.

4.The vacuum Transformer Oil Purification System use the advanced fuzzy oil temperature control system , the oil temperature upper and lower bounds can be arbitrary set , make the oil temperature to be interval control.

5. The vacuum Transformer Oil Purification System adopts high automatic degree and the oil temperature level to realize automatic control and automatic protection, safe and reliable, simple operation and convenient.

Insulation Oil Purifier 2024 version Technical Data

Parameters | Unit | ZY-10 | ZY-20 | ZY-30 | ZY-50 | ZY-100 | ZY-150 | ZY-200 | ZY-300 |

Flow rate | LPH | 600 | 1200 | 1800 | 3000 | 6000 | 9000 | 12000 | 18000 |

Working vacuum | MPa | -0.06 ~ -0.095 |

Working pressure | MPa | ≤0.4 | ≤0.5 |

Working without Trouble | H | ≥4000 |

Continuous Working | H | ≥150 |

Temperature range | ℃ | 20 ~ 80 |

Power supply |

| 380V, 3 phase, 50 Hz (or as per your requirements) |

Working noise | dB(A) | ≤ 80 |

Heating power | KW | 12 | 13 | 15 | 30 | 48 | 60 | 72 | 90 |

Total power | KW | 13.5 | 14.5 | 16.5 | 33.5 | 53 | 65 | 76 | 98 |

Inlet/outlet caliber | mm | φ25 | φ25 | φ25 | φ32 | φ42 | φ50 | Φ60 | φ65 |

Weight | Kg | 230 | 250 | 280 | 300 | 550 | 700 | 950 | 1200 |

Size | mm | 1000×

800×

1200 | 1100×

900×

1350 | 1150×

900×

1450 | 1200×

950×

1580 | 1600×

1000×

1800 | 1650×

1100×

1850 | 1800×

1200×

1900 | 1900×

1200×

2000 |

After Filtration

(Performance) | Moisture (Water Content) | ≤ 4 PPM |

Gas Content | ≤0.1% (Vol) |

Impurities Degree (Filtration precision) | ≤ 1 micron |

Breakdown Voltage (Dielectric) | ≥70 KV |

Cleanliness | ≤NAS 1638 Grade 6 |

Note: 1. The dimension and weight will be changed with changing of technical specs. 2. All the specs can be customized according to client's requirements. |

We are profession exporter, provide service worlwide!

Your inquiry will be replied within 12 hours due to time zone difference

Your inquiry is warmly welcomed!

HOPU Website: www.hopufiltration.com

Branch 1: www.hpoilsolution.com

Branch 2: www.hopuoilpurify.com